Zinc Layer Anodes (ZLA)

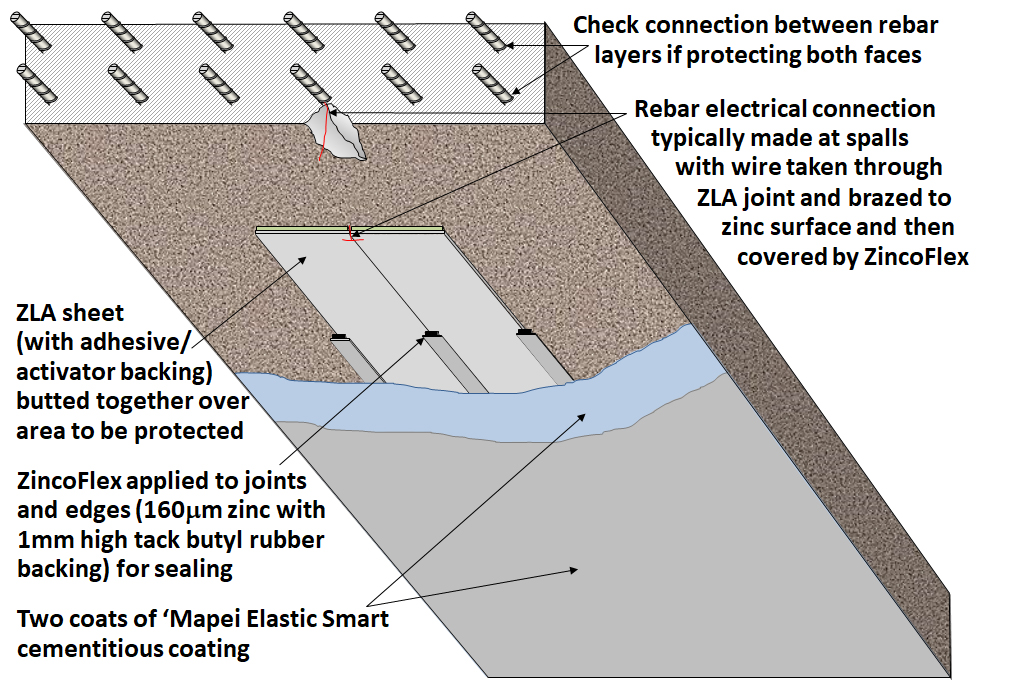

Zinc Layer Anode is corrPRE’s (the manufacturer) name for their zinc sheet backed with activator paste, adhesive and backing sheet that is applied to a concrete surface to provide sacrificial galvanic cathodic protection to actively corroding reinforcement.

Application Areas

The system is perfect for many cathodic protection projects as:

- The anode provides sufficient current to polarise the reinforcement such that AS 2382.5 protection criteria are met.

- Provides current uniformly over the concrete surface ensuring all bars receive protection

- Can be applied to localised areas, e.g. beam corners, step risers, isolated plinths.

- Does not require core holes for locating anodes and so is a silent application.

- Is easily covered by a decorative and waterproofing coating.

ZLA has been applied to:

- repair bridge columns

- Bridge beams

- repair balcony soffits and edges

- Precast façade elements

- Pipes

- Wharf beams & soffits

- Car parks

- repair historic structures

- repair lintels

Technical Data

- Weight 3350 kg/m3

- Zinc 1760 kg/m3

- Adhesive 1440 kg/m3

- Paper 150 kg/m3

- Zinc 99.9% pure

- Conductive gel resisitivity<10,000ohm cm

- Allowable temperatures

- Storage < 40°C

- Avg. Operations 4 to 50°C

- Short term -40 to 70°C

- Maximum electrical capacity 0.13 Amps/yr/m2

- Roll width: 25cm

- Roll Length: 20m

- Roll Surface Area: 5m2

- Packed 12 Rolls/box

The Simplest CP System Ever

Galvanic anode systems are much simpler than impressed current systems and the ZLA system is particularly simple. In the best case scenario simply clean the surface, pull of the ZLA backing tape, press the anode to the concrete surface and connect the ZLA to the reinforcement.

Advantages

- No wiring installation or external power source needed

- No regular checking and adjustment of current supply

- Simple and easy installation.

- No noise and vibration of breakout or coring

- Cost-effective and attractive

- Offers sufficient current in dry environment

- No risk to prestressing

- Installed to comply with Australian Standard 2382.5 and European standard EN 12696 protection criteria.

- Repair mortars : mineral based sand–cement mixtures

Precautions

- Clean, coating free concrete surface

- Avoid polymer based repair-mortars (resistivity <30,000ohm cm required)

- Zinc can be overcoated with cementitious and acrylic based topcoat. Required to give protection to exposed zinc surface.

- Seal ZLA edges or avoid situations with running water

- Longevity approx. 20 years but each system designed using SRCP software

SRCP anodes available:

Zinc Layer Anodes (ZLA), Roll Anodes, and GSC Super Anodes give lower cost true cathodic protection systems for concrete that can be used:

- where electrical systems are unavailable (e.g. projects with many isolated areas)

- where impressed current systems are uneconomic (e.g. small areas)

- on projects where electrical systems are not suitable (e.g. hazardous area)

- in areas where wiring is not practical (e.g. many mine site areas)

- where localized protection is required (e.g. at corners, joints or areas of localized low cover)

- where incipient anodes may commence active corrosion

The anodes are designed around anode paste that was developed after several years of research. It enable a high current density, produces reactions that do not lead to breakdown, prevents passivation.

CorrPRE’s High Output Galvanic Anodes Revolutionise Reinforcement Corrosion Repair

-

No need to break out sound but contaminated concrete

-

Major saving in breakout cost and effort

-

Noise reduction as no hard breakout

-

Risk of structural failure reduced as reinforcement not debonded

-

Less risk of vibration damage to setting mortar in surrounding repairs

-

Contract period and cost reduced as less hard work to do

Full cathodic protection by galvanic action at patch and surrounding areas

-

no wiring or control systems

-

no monitoring required

-

Simply installed, no CP expertise required