Controlling And Monitoring of Corrosion in Cathodic Protection Systems

Cathodic Protection (CP) Control Systems

For the controlling and monitoring of corrosion specialist equipment is required. Various devices are offered by SRCP that are useful for practitioners who design or install cathodic protection systems.

Products provided include:

- Data loggers for Cathodic Protection systems

- Current limitors

- Embedded reference cells

- Camur II

The Camur II ICCP control system is now available to customers to use for testing. Contact SRCP to find out more.

Click the following link to see the Camur II Cathodic Protection Control and Monitoring System detailed animation.

Camur II CP Control System

Camur II is a distributed data logger system designed for measurements in concrete. It is a scalable system. You will find cost-effective solutions for systems with few sensors installed in a small area or systems with hundreds of sensors spread over several hundred meters.

Starting in the measuring point the Camur II node connects your sensor to the Camur II Bus. Different kinds of sensors need different kinds of signal conditioning, consequently there are several types of Camur II nodes. For example the Camur II P-node is designed to measure the potential between a reference electrode and the rebar. Camur II LPR-node is designed to perform LPR measurement connected to rebar, reference- and counter electrode.

The Camur II Bus connects all your Camur II nodes with a Camur II Controller. The Camur II Bus consists of a power and a CAN-bus cable.

Observe that you only need one set of cables to connect all your nodes to the Camur II Controller. The Camur II Bus need only pass the measurement points in the shortest way. The Camur II Controller is the supervisor of the Camur II installation. It is responsible for the configuration of the system. It collects and stores the data from your sensors, sets alarms and logs all important events in the system.

Finally you need the user interface. The Camur II Monitor software runs directly on the Camur II Controller or on a remote PC.

MnO2 Half Cells

The ERE 20 is a true, long life Reference Electrode, which can be cast into the cover concrete to check polarised and depolarised potentials of cathodic protection systems and to monitor the corrosion state of reinforcing steel in structures.

Normally installed in newly cast concrete, but the electrode can also be installed in existing structures.

Based on proven battery technology, the ERE 20 is a true half-cell using a manganese dioxide electrode in corrosion resistant steel housing with an alkaline, chloride-free gel.

The pH of the gel corresponds to that of pore water in normal concrete, so errors due to diffusion of ions through the porous plug are eliminated.

The potential of ERE 20 is virtually independent of changes in the chemical properties of the concrete. It can, therefore, be used in wet or dry concrete, whether exposed to chlorides or to carbonation.

Easily Installed Robust Half Cell

Advantages

- Control of cathodic protection

- For potential measurements in wet and dry concrete

- Can be exposed to chloride or carbonation

- Does not induce corrosion in steel

- Does not change potential of steel

- Easy to install in new or old structures

Project Examples

Virginia Transport Research Council used the ERE 20 probes as an integral part of their embeddable corrosivity measurement instrument (right).

The National Research Council of Canada used the ERE 20 in its research on structures on the performance of inhibitors because of the cells proven stability on old installations.

ERE 20 half cells were used in one of Europe largest nuclear power reactors (TVO OL3).

Technical Data

MnO2 Half Cell

- Typical potential in saturated Ca(OH)2 at 25C +160mv (SCE)

- Approximately 100mV more positive with respect to Cu/CuSO4 reference electrode.

- Stability. At constant temperature shift < +5mv

- Internal resistance: < 5000 ohm after soaking in water

- Temperature Range: -10 to +40°C

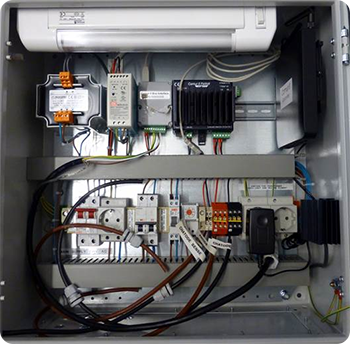

4 Channel Cathodic Protection (CP) logger

corrPRE manufacture a 4 channel datalogger (channels all galvanically isolated) which is specifically developed for cathodic protection systems.

This datalogger can be integrated independently in both galvanic and impressed current CP systems and has an input impedance of 10 GigaOhm, which secures stable reference electrode readings.

It is equipped with a current input for automatic depolarization measurements and within the first 20 seconds of each measuring session logs 10 measurements per second for accurate instant-off readings and valuations.

The standard SD card will log all data in easily accessible files, which can be opened with Excel for personalized data analysis.

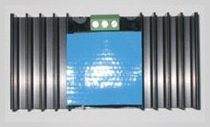

Current Limiter

One of the most challenging problems impressed current cathodic protection engineers encounter are problems created by considerable variations of current and potential over the structure which is difficult to avoid.

These potential variations are mainly caused by:

- Anode resistance variations

- The lineal resistance of the anode feeders cable

- Variations in the electrolyte’s resistivity.

corrPRE developed and manufacture the Current Limiter to avoid excessive current outputs by anodes caused by above described problems. The Limiter’s current output should be adjusted at a pre-set value, which should be the same as the anode’s “current rating” specified by the manufacturer.

No matter what the anode’s resistance and voltage at the anode feeder cable will be (max. 30 Volt), the current flow through the limiter will never exceed the pre-set current value.

A Simple way to Balance Currents in Impressed Current CP systems

Advantages

- A better current distribution over the multiple or distributed anode system

- Avoiding high anode consumption rates, which will increase the anode’s longevity above its design-life

- Making the CP-installation much easier and simpler by using simple AC/DC transformers without the need of current/voltage controllable power supplies

- Small, cheap design and easy to install

- Needs no external power source, as it is powered by the anode feeder cable

Model 5-50

For 5-50mA ranges (no power required)

Model 50-500

For 50-500mA ranges (no power required)

Model 250-50

For 250-2000mA ranges (AC powered)