Cassette Surface Mounted Ribbon Anode System

Cassette is a ribbon anode impressed current cathodic protection (ICCP) system for the repair of concrete structures where the reinforcement is corroding. Instead of burying the ribbon anode in the concrete it is mounted in an inert panel with a felt pad to spread the current from the ribbon to the concrete surface.

Cassette is used where ever there is limited access or wet conditions. It is rapidly installed with limited noise, no mess and with inert components the risk of failure is low. More importantly its simple installation generally leads to significant cost savings on the project.

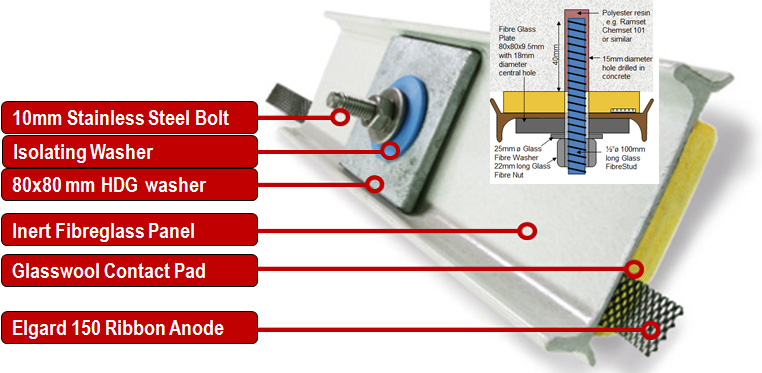

Cassette System Showing Steel and Fibre Glass Bolts

The ‘Cassette’ comprise an inert fibreglass frame loaded with a MMO titanium ribbon on a conductive felt.

The frame is clamped to the concrete using stainless steel or fibre glass bolts. This gently presses down the felt. The Elgard 150 mesh ribbon anode is sandwiched between inert felt and glass fibre cassetts so acidification is not an issue. Acidification is a major cause of failure of slotted ribbon anodes in wet conditions.

The felt is made conductive by application of a gel when used in dry environments or by seawater in spalsh zones. A current is passed between the titanuium ribbon mesh and the reinforcement to provide cathodic protection to the reinforcement.

All components of the system are resistant to corrosion and hence the system can be used in corrosive environements such as the underside of wharf decks. The system is easy to use in restricted or confined spaces as it is:

- located on the surface of the concrete and hence there is very little preparation work required

- prefabricated and can be rapidly installed.

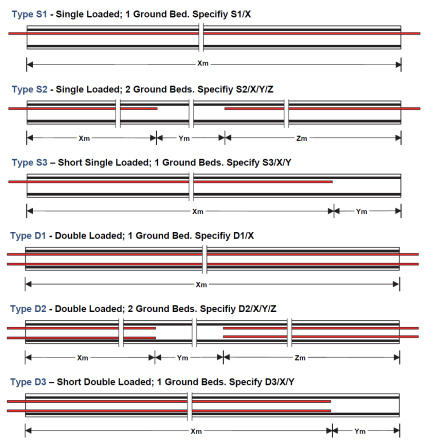

Cassette Types for Different Groundbed Layouts

Because the ICCP system is contained within the cassette it is relatively vandal proof and ideal for car parks, bridges and wharfs.

Australian projects include the High Level Bridge in Perth and a coal conveyor tunnel in Queensland.

Applications

There are a number of proven cathodic protection systems available. The difficulty is determining which is the most appropriate one for a particular structure. All systems will have their merit, but the Cassette system has a number of features that make it suitable for some specific uses:

- Assembled units with very little concrete preparation make it ideal for restricted access or confined space areas

- Water and seawater do not cause corrosion of the system and assist with system conductivity hence the system is ideal under wharves, in leaking basements and tunnels and on mine or industrial sites where inundation is possible

- No special skills or equipment are required and the system can be installed by any competent repair contractor with an electrician.

For examples of specific applications follow the main menu links at the top of the page through to concrete repair & protection or take a look at the SRCP projects page.