DurAdjust 485 Monitoring System

The durAdjust485 monitoring system can monitor the corrosion of structures whether there is no CP system or if there is a separate CP system with no inbuilt monitoring. The durAdjust485 system can be incorporated into a durApower485 system as it can use the monitoring input values as control parameters for other durApower485 outputs.

The system comprises a Central Control Unit (CCU) connected by a bus cable, fibre optic or wireless connection to remote stations as described below.

DurAdjust 485 Central Control Unit

CommunicationsThe durAdjust485 central control unit (picture right is the mounting plate for the CCU) typically comprising:

- Cabinet

- The PC computer running durAdjust software. The PC is an all-in-one industrial unit (made by Pro-face). It is fitted with a HUB allowing 4 branches.

- Large touch screen

- 1 No GSM modem (now more commonly a wireless router)

- durAlpr, durAstore and durAhold componets as described for the substations below.

The computer runs Windows XP Embedded with the dedicated durAdjust485 software and the remote modem or wireless router (NetOp Remote Control Host) software which is held on the compact flash (CF) card built into the computer. When the unit is switched on these programs and on-screen-keyboard and mouse control are self started and operate. The system setup is determined by the ‘ini’ (initialisation) file.

For more complex functions an external USB keyboard and mouse can be used. This additional sophistication is generally only required during the initial system start up and set-up. The USB connectors are on the back of the computer and can be accessed when the flap on the front panel of the cabinet has been opened.

CPI installs an ‘ini’ file for the intended use in accordance with the information provided by the client. For normal operation the operator can go straight to the system section.

The durAdjust485 control system can be remote controlled by modem, with all the functions available on the function buttons and external keyboard also available from the remote control. The remote control can be made from any PC with the right software (NetOp Remote Control Guest) and modem.

The durAdjust485 substation components can be quite varied depending on the requirements of the structure. Each substation contains one durAstore module and up to eight durAhold485 and up to eight durAlpr. The units are modular and mounted in a 19inch 3HE rack.

It can comprise:

- Cabinet – (500 wide x 555 high x 270mm deep)

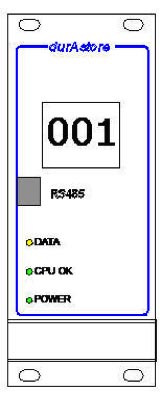

- durAstore – the durAstore card is a datalogger that stores all the data for the substation until uploaded to the CCU. It has a thumb switch on the front used to set the durAstore general address. There is galvanic isolation between the data bus and connected modules. It has three light diodes to show status (data transfer, internal program running power to card). A durAstore is required in each substationdurAlpr – up to 8 durAlpr cards can be installed for measurements of linear polarisation resistance, zero resistance current, relative humidity and temperature using the Pt1000 standard. The LPR module is an intelligent device that is able to autonomously ramp a current over time to achieve a desired potential. The LPR-board performs the following

- Measures the natural potential.

- Applies an increasing current in steps of 30.518 nA until the potential measured with current on is the VLSP measured in mV. Between each current step is a delay. The delay is a minimum 300 micro seconds and can be increased in steps of 100 micro seconds. The board calculates this delay so the polarisation rate is 10 mV per second. The polarisation rate can be changed.

- Switches off the current and makes the instant off potential. A delay from switching off the current and doing the potential reading is set to 30 micro seconds.

- Apply an increasing negative current until the potential measured with the current on is changed (similar manner to the positive polarisation).

- Switch off the current and makes the instant off potential.

- durAhold – up to 8 durAhold half cell measuring cards can be used. That’s 64 No reference electrode inputs altogether. These are described in more detail in the durApower485 system.

Communications

All the durAdjust modules are connected through the 485 data bus and transmit data at 19,200 baud, 8 bits, Even parity, 1 stop bit , Half duplex. The RS485 can be run in copper cable (1 twisted pair), fibre optic cable and wireless radio.

Maximum distance between substations using 1 twisted pair of copper cable is 1100m. The distance can be increased using repeaters.

Maximum distance between substations using fibre optics depends of the fibre type and can be up to 25km between RS485 repeaters.

Maximum distance using wireless radio depends of the transmitting power, aerials and obstructions between radio modems. Typical range for a radio modem using a free channel in a city area is 1-2km and in flat land 5-10km. Repeaters can be used.

The address consist of:

- Address of durAstore (1-254). Typically there is a durAstore for each rack.

- Address of module set on the backplane (1-8).

- Type of module, durApower, durAhold, durAlpr etc.