GSC Super Anodes – True CP of Patch Repairs

GSC Super Anodes are designed to be cast into patches during concrete repairs to provide cathodic protection of the reinforcement in the patch area and cathodic prevention to surrounding reinforcement that may have become an incipient anode.

Like all corrPRE anodes GSC Super Anodes have a high polarising capacity due to the patented activator used. Because they give full cathodic protection only loose and fractured concrete needs to be remove.

GSC Super anodes remove the need for hard breakout associated with other anodes used for cathodic protection.

GSC Super Anodes lead to professional long lasting concrete repair at a fraction of the cost of full patch repair involving breakout behind the reinforcement.

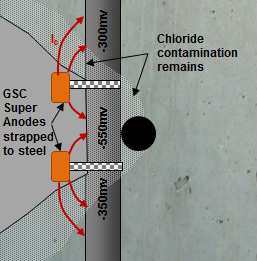

Providing full cathodic protection using GSC Super Anodes eliminates the need for expensive breakout of hard, sound but contaminated concrete. Such breakout is necessary in conventional concrete repairs, or repairs using cathodic prevention as otherwise the reinforcement would continue to corrode.

Schematic of GSC Super Anode in a patch of a concrete repair.

GSC Super Anodes are specifically designed to cathodically protect reinforcement in concrete. The anodes are embedded within the repair concrete or mortar and are electrically connected to the reinforcement. They are perfect for use in localised patching of corrosion induced damage but can also be used with other corrPRE sacrificial anodes (e.g. Roll Anodes and Zinc Layer Anodes) to cathodically protect the whole structure.

-

GSC Super Anodes are made of laminated zinc with a 99,99% purity. The laminations ensure that all the zinc is used. Solid zinc anodes generally block and stop working when only partially consumed.

-

The zinc is covered by two layers of different zinc activator paste (ZAP). The patented ion conductive self-moistening ZAP keeps the anodes active during their entire life.

-

Each anode is sealed in a plastic bag to avoid contamination during shipping and storing.

-

Prior to application the packing is removed, and the anode is ready to be applied.

Application Areas

Suitable for all localised patch repairs of corrosion damage. When should they be used? All concrete repair patches! For larger repairs, or repairs where there is widespread activation but little damage, use Roll Anodes or Zinc Layer Anodes.

-

Simple installation. Just bolt to the reinforcement.

-

Very low cost compared to alternatives of full breakout of contaminated concrete, short repair life or impressed current CP

-

Pre-stressed or post-tensioned tendons will not be subject to hydrogen embrittlement due to reasonable operating potentials

-

Needs no service or monitoring

-

Current densities are natural self-adjusting depending on the current request by the structure

GSC Super Anode in a patch repair

GSC Super Anodes for full cathodic protection

For true cathodic protection an ability to provide high polarisation is required and most galvanic anodes don’t have that ability. corrPRE’s anodes are unique and have a high polarisation capability due to the nature of the patented activation paste.

- GSC Super Anodes give enough current in dry and arid environments for true Cathodic Protection

-

At the end of the design life the reinforcement will be repassivated and anode replacement will probably not be necessary

-

When applied in aggressive environments the current densities are highly comparable with impressed current systems

-

Full Cathodic Protection means no breakout of sound but contaminated concrete

Each of the anodes below provide true cathodic protection and that means only loose and fractured concrete needs to be removed. No hard breakout is required.

Calculated Design Life in years for different reinforcement configurations, anode types and anode spacing

|

Bar |

Space |

Anode |

ML10 |

ML30 |

||||||||||||

|

32.7 |

25.0 |

19.8 |

16.0 |

11.1 |

9.5 |

8.2 |

11.1 |

9.5 |

8.2 |

6.3 |

4.9 |

4.0 |

3.3 |

|||

|

Spacing mm |

175 |

200 |

225 |

250 |

300 |

325 |

350 |

300 |

325 |

350 |

400 |

450 |

500 |

550 |

||

|

Zn Kg/m2 |

5.88 |

4.50 |

3.56 |

2.88 |

2.00 |

1.70 |

1.47 |

6.00 |

5.11 |

4.41 |

3.38 |

2.67 |

2.16 |

1.79 |

||

|

As mmst2/mconc2 |

Life (yrs) |

|||||||||||||||

|

28 |

100 |

1759292 |

46 |

35 |

27 |

21 |

14 |

12 |

10 |

47 |

40 |

34 |

25 |

20 |

15 |

12 |

|

24 |

100 |

1507964 |

54 |

41 |

32 |

25 |

17 |

14 |

12 |

55 |

47 |

40 |

30 |

23 |

18 |

15 |

|

20 |

100 |

1256637 |

65 |

50 |

39 |

31 |

21 |

17 |

15 |

67 |

57 |

49 |

37 |

28 |

23 |

18 |

|

16 |

100 |

1005310 |

82 |

63 |

49 |

39 |

26 |

22 |

19 |

84 |

71 |

61 |

46 |

36 |

29 |

23 |

|

16 |

150 |

670206 |

125 |

95 |

75 |

60 |

41 |

34 |

29 |

128 |

108 |

93 |

71 |

55 |

44 |

36 |

|

16 |

200 |

502655 |

167 |

128 |

100 |

81 |

55 |

47 |

40 |

171 |

145 |

125 |

95 |

75 |

60 |

49 |

|

12 |

200 |

376991 |

224 |

171 |

135 |

109 |

75 |

63 |

54 |

229 |

195 |

167 |

128 |

100 |

81 |

66 |

Small GSC Anodes for cathodic prevention

Where a low cost anode for cathodic prevention is required the GSC 5/10P is designed for use at 500x500mm centres. This anode is designed to compete with other anodes that provide a low polarisation to slow the corrosion rate or to maintain cathodic prevention against incipient anodes. Like other anodes of this type the GSC 5/10P anode does not give cathodic protection and hence concrete around actively corroding reinforcement is typically removed. The GSC 5/10P anode has several times the zinc mass of other anodes of this type to give a long life.

corrPRE has also introduced a true clip on anode. This ‘clip on’ anode has a metal clip that is pushed onto the reinforcement to make the connection. The anode is contained in a solid grout.

Packing

-

ML30/10 12pc/Carton

-

ML10/10 24pc/Carton

-

ML5/10P 48pc/Carton

Installation

-

Remove cracked and delaminated concrete

-

Tie on anodes and check electrical continuity. Resistance between anode and rebar should be less than 1 ohm.

-

Reinstate with conventional patch materials with a resistivity as low as practically possible.