HISEO Titanium MMO Coated Anodes

HISEO anodes are ASTM B265 Grade 1 mixed metal oxide (MMO) coated titanium manufactured by Chemical Newtech of Italy. They are available as ribbon mesh, net and tube anodes for impressed current cathodic protection.

The Material

Titanium

HISEO anodes are ASTM B265 Grade 1 Titanium coated with a mixed metal oxide (MMO) coating. The titanium has the following properties:

Electrical resistivity: 0.006 Ω/m

Tensile strength: 0.24 MPa

Yield strength: 0.17 MPa

Elongation: 25%

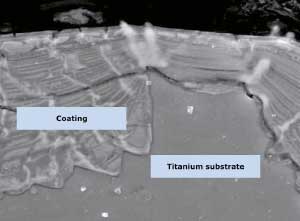

The titanium is thermally treated (annealed) and etched in sulfuric or hydrochloric acid to obtain the necessary roughness for the optimal coating thickness.

MMO Coating

The catalysts are oxides of iridium or ruthenium alone or in combination. The catalyst is stabilsied with oxides of titanium, tantalum, niobium and tin.

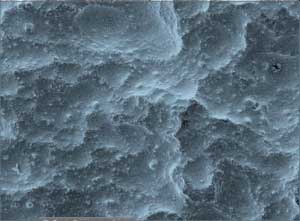

Magnified Image on the Surface of the MMO Coating.

The coating (catalysts and stabilisers) is obtained by thermal decomposition in a furnace solution of salts, typically chlorides or nitrates and is built up on the titanium in up to 16 layers to give the required thickness.

The life of the anode at a given current is dependent on the coating thickness. The performance of each batch of anodes is verified by accelerated tests where the anode is placed in sulfuric acid or sodium sulfate and a current of 3 to 10KA/m2 is passed.

Cross Section through MMO Coated Titanium Showing Roughness of the Base Titanium.

Anodes For Concrete

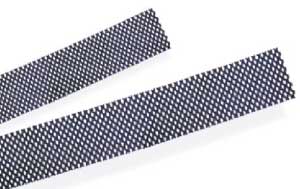

Ribbon Anode

Ribbon mesh is available in 10, 12, 13, 15, 20 and 25mm widths. The titanium is 0.6mm thick and expanded thickness is 1.15mm. The main application is cathodic protection of current. It is supplied in 50m rolls and has the following properties:

|

Width (mm) |

20 |

15 |

13 |

|

Weight (kg) |

1.4 |

1.1 |

0.9 |

|

Resistance (Ω/m) |

0.24 |

0.35 |

0.36 |

|

Max current density mA/m2 |

|||

|

For 100 year life |

110 |

||

|

Short term limit |

220 |

||

|

Max current for |

|

|

|

|

100 yrs (mA/m) |

5.3 |

3.9 |

3.5 |

Net Anode

Net anode is available in three mesh sizes. Its primary application is for reinforced concrete but it is also used for dehumidification.

Cross Section through MMO Coated Titanium Showing Roughness of the Base Titanium.

A 50m long x 1.2m wide roll is supplied as follows:

Long. (mm) | 38 | 22 | 19 |

Transv. (mm) | 85 | 62 | 38 |

Weight (kg) | 0.23 | 0.29 | 0.33 |

Max current density

mA/m2 | 20 | 30 | 45 |

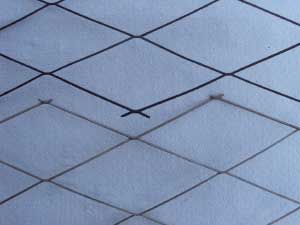

Cross fasteners are designed to pin the net anode to a concrete surfaces.

Cross Fasteners Holding Ribbon Mesh in Place.

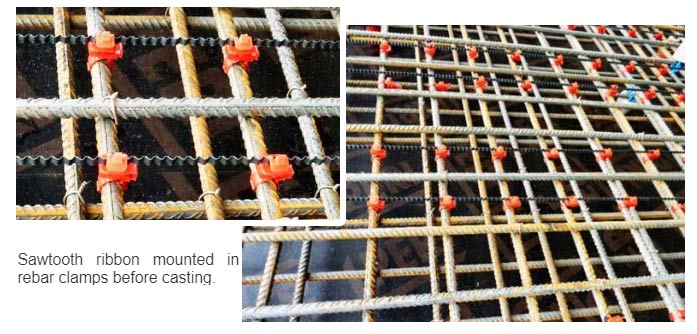

MMO Titanium Sawtooth Ribbon Anode

Sawtooth ribbon anodes are manufactured using a titanium substrate. It is coated with Mixed Metal Oxide coating consisting of IRO2 / Ta2O3 and is suitable for use in all cathodic protection applications.

Independent laboratory testing has proven the MMO coating is superior to other MMO coatings currently used. Strict quality control procedures are followed throughout the coating process to ensure proper coating adhesion and thickness.

Sawtooth ribbon is 0.3mm thick, has a peak to trough height of 3mm and comes in two widths:

No. |

Width |

Surf Area |

Current |

Resistance |

1.200.100 |

6.35mm |

0.0287m2/m |

3.15mA/m |

0.182ohm/m |

1.200.200 |

12.7mm |

0.0574m2/m |

6.30mA/m |

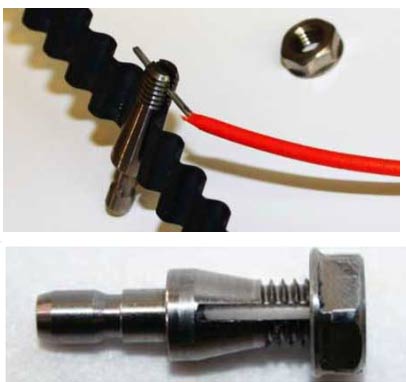

Sawtooth Connector

Titanium connector with titanium nut to connect 1.2mm feeder wire to 6.35mm Sawtooth anode ribbon. The connector is fastened to the concrete with a Rawl plug.

Sawtooth End Clamp

The end clamp is used to tighten the sawtooth ribbon from one end to the other. At least one of the end clamps is also used to connect a 1.2mm titanium feeder wire. A titanium nut is used to fasten the feeder wire and sawtooth ribbon to the built in titanium connector.

Sawtooth Holding Disc

20mm diameter x 33mm high orange plastic fixings that are tapped into a hole drilled in the concrete. The threaded length that fits into the hole is 8mm diameter.

Sawtooth Rebar Clamp

The clamps fits around the reinforcement and the sawtooth ribbon anode clips into the clamp. The clamp comes in five different sizes with different colours.

Blue |

12mm rebar |

No 1.200.312 |

Red |

16mm rebar |

No 1.200.316 |

Yellow |

20mm rebar |

No 1.200.320 |

Green |

25mm rebar |

No 1.200.325 |

Yellow |

32mm rebar |

No 1.200.332 |

Anodes For Steel

HISEO Wire

MMO coated Ti wire is supplied in 100m rolls. It is used for cathodic protection of metal in aqueous and soil electrolytes. It provides high protection in fresh, brackish or salted water. It has the following properties:

|

Ext. diam. (mm) |

1.5 |

3.0 |

|

Resistance |

0.35 |

0.09 |

|

Current |

||

|

Fresh A/m |

0.5 |

2.5 |

|

Sea Water A/m |

3.3 |

6.0 |

|

Soil A/m |

0.3-0.5 |

1.5-2.5 |

Cross Section through MMO Coated Titanium Showing Roughness of the Base Titanium.

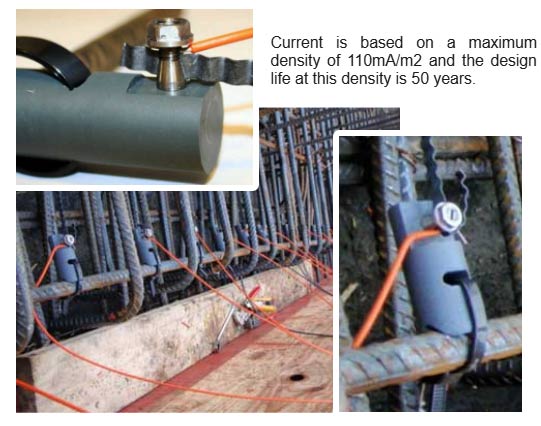

HISEO Tube

MMO coated Ti tube is supplied in 1m lengths. The coating is designed specifically for the exposure.

The maximum current (Amps) is as follows:

| Width | 20mm |

| Weight | 0.27 kg/m |

| Yield strength | 0.17 MPa |

| Current | |

| Without backfill | 4 A/m |

| With backfill | 2 A/m |

| Life tested to | NACE TM108 |

App1 is soil or fresh water or brackish water. App 2 is seawater.

At temperatures below 5 degrees celcius the current is reduced to 50% for App1. At temperatures below 10 degrees celsius the current is reduced by 20% for seawater

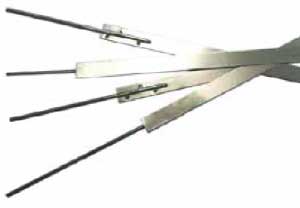

HISEO Strip

MMO coated Ti strip is supplied in lengths up to 3m for cathodic protection in soils.

HISEO strip has the following properties:

|

Width |

20mm |

|

Weight |

0.27 kg/m |

|

Yield strength |

0.17 MPa |

|

Current |

|

|

Without backfill |

4 A/m |

|

With backfill |

2 A/m |

|

Life tested to |

NACE TM108 |

General Products

The following products are used with anodes for concrete and anodes for steel.

Current Distributor

Current distributor is uncoated titanium strip as follows:

| Width | 20mm |

| Weight | 0.27 kg/m |

| Yield strength | 0.17 MPa |

| Current | |

| Without backfill | 4 A/m |

| With backfill | 2 A/m |

| Life tested to | NACE TM108 |

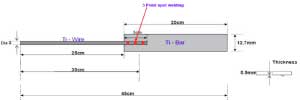

Power feeder connectors are titanium strip welded on 3mm diameter titanium rod. It is used to connect between the power sources and anode in concrete.

Chemical NewTech

Chemical Newtech (CNT) produces insoluble anodes coated with electrocatalytic layer based on the noble metals group. They are certified to ISO 9001

CNT can also manufacture electrodes specific to an application suggesting appropriate coatings and configurations. They are located in Capriolo, Italy but the majority of their sales are international.